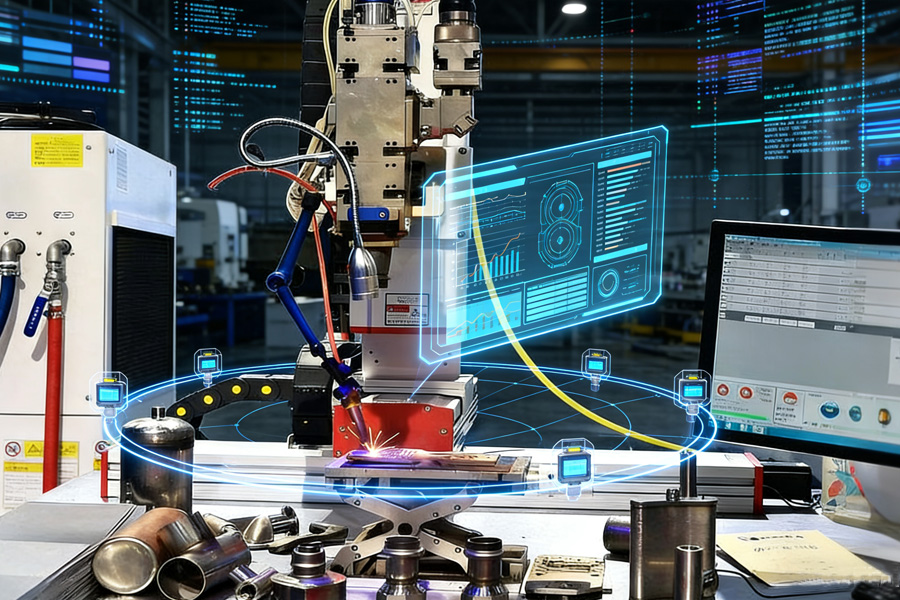

As a core process in modern manufacturing, laser welding technology, empowered by robotic automation, is achieving unprecedented breakthroughs in precision and efficiency. We delve into this revolutionary technology to reveal how it is driving transformations in production methods across key industries.

Technological Breakthrough: Intelligent Robots Reshaping Welding Processes

High degree of automation

Enables fully automated welding, reduces manual intervention, and improves production efficiency.

Stable welding quality

Ensures consistent robotic welding processes, delivers high-quality weld seams, and minimizes defects.

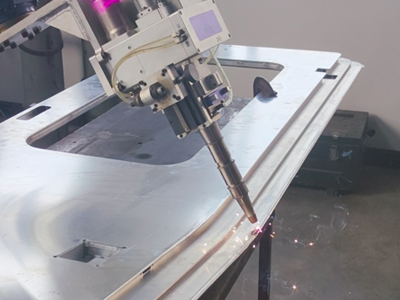

Adaptability to complex workpieces

Six-axis robotic arms flexibly adjust welding paths and angles, handling various 3D curved structures suitable for welding complex components.

Industry Applications: From New Energy Vehicles to Specialized Equipment

The aerospace industry relies on robotic welding systems to achieve precision joining of critical components such as engine parts and cabin structures, meeting performance requirements in extreme environments.

In specialized equipment manufacturing, robotic welding technology has been successfully applied to high-difficulty processes such as multi-layer composite welding for bulletproof armor and sealing welding for nuclear power equipment, demonstrating exceptional process adaptability.

Robotic Laser Welding Solutions for High-Speed Train Door Assembly

Laser Robotic Welding Solutions for High-Temp/High-Pressure Exhaust Systems

Future and Application Outlook: Integration of Laser Welding and Robotics

Technology evolution: Intelligence and integration are emerging as new trends, with next-generation robotic welding systems evolving in the following directions:

Real-time quality monitoring system: Achieves comprehensive welding process monitoring through multi-sensor fusion technology.

Adaptive process adjustment: Autonomously optimizes welding parameters based on AI algorithms.

Cloud-based collaborative manufacturing: Supports remote programming and production data management.

In terms of applications, it will accompany industrial upgrades to meet demands for efficient, high-precision welding; reduce costs and improve efficiency by replacing traditional welding processes; and achieve greener manufacturing with enhanced energy savings and environmental protection.