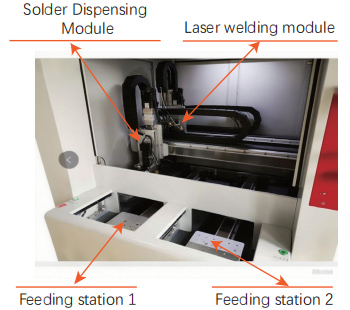

BV-SW100 Integrated Laser Solder Welding System Developed by BUVA Tech, the BV-SW100 integrates automatic solder dispensing and laser welding into a single station. Through precision wire feeding, accurate laser heating, and real-time positioning correction, it achieves a fully automated closed-loop process from material supply to soldering eliminating reliance on manual operation.

| Laser Source | Semiconductor Laser |

|---|---|

| Laser Power | 100W /200W (Optional) |

| Cooling Method | Full air-cooling/water-cooling |

| Positioning Method | Coaxial CCD automatic positioning |

| Control Method | PC control, temperature feedback, constant temperature welding, dual station |

| Air Source | 0.4~0.6MPa (dry and clean air) |

| Operating Environment | Temperature 25±5°C, Humidity <60% (non-condensing) |

| Working Voltage | AC 220V/50Hz |

Integrates processes like automatic positioning, tin application, and welding. Reduces repetitive handling, boosting production efficiency.

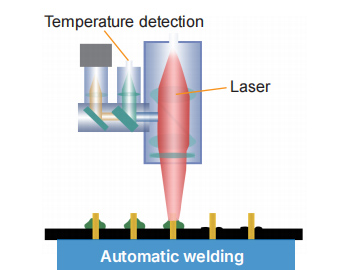

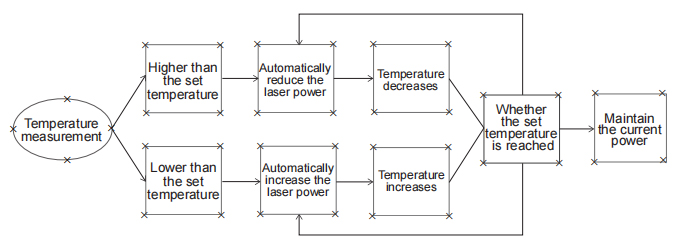

With high-precision infrared temperature detection, it enables reliable constant-temperature welding processing, as well as real-time monitoring and intervention of solder joint quality.

Automatically stores and recalls processing parameters. CCD-enabled auto-alignment for welding, minimizing manual intervention.

Integrates processes like automatic positioning, tin application, and welding. Reduces repetitive handling, boosting production efficiency.

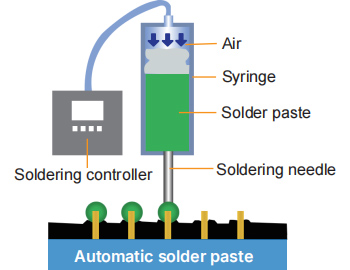

Integrated soldering and welding in one unit

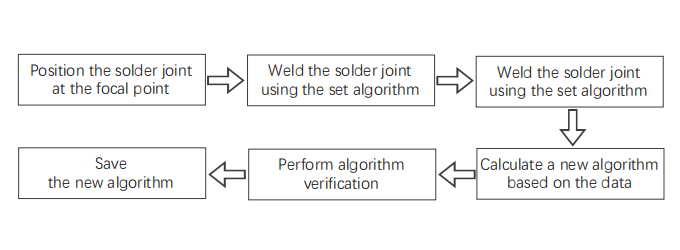

Closed-loop Control Principle