Laser-arc hybrid welding is a process that physically couples a focused laser beam with an arc to form a composite heat source acting on the material surface, achieving welding through the movement of the heat source. This technology couples two heat sources with distinct physical properties and energy transmission mechanisms, leveraging their synergistic effects to compensate for the defects of single-source welding.

It offers advantages such as high efficiency, superior quality, and energy conservation, demonstrating significant superiority in the field of medium and thick plate welding.

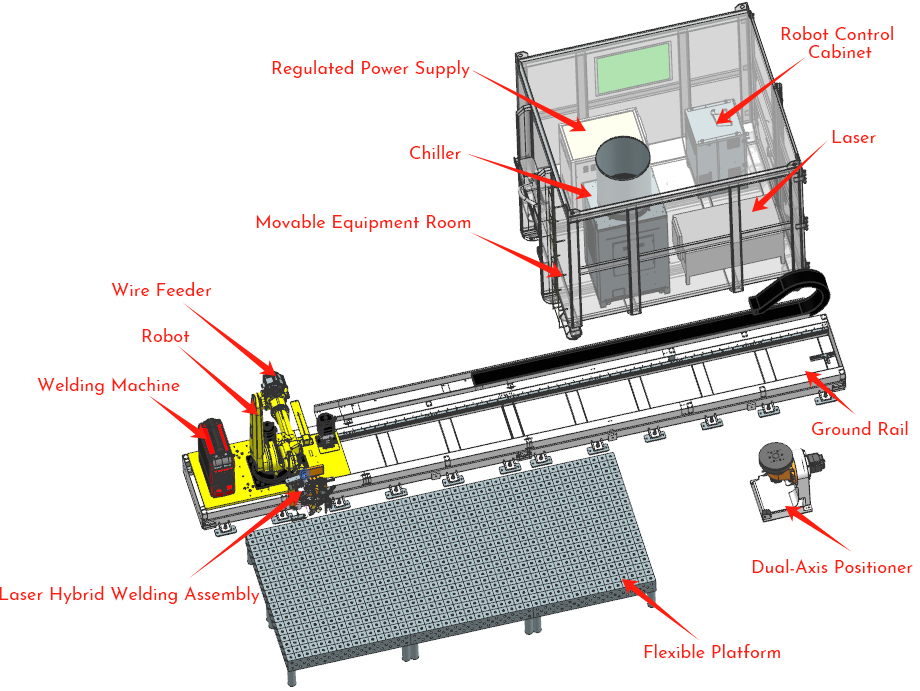

| Laser Generator | 6kW, 12kW, 15kW Continuous Laser |

|---|---|

| Water Chiller | Cooling Capacity >20kW |

| Welding Head | Customized |

| Arc Welding Power Source | 500A |

| Weld Seam Tracking | (Sensor + Recognition + Software) |

| Robot | Six-Axis, 50kg Load Capacity |

| Welding Platform | Three-Dimensional Flexibility |

| Positioner | Customizable Dimensions and Load Capacity (Interlockable with Manipulator) |

| Control System | Customized |

Cost Reduction in Equipment and Consumables: The popularization of domestic laser generators has driven down equipment costs. The increased penetration depth of hybrid welding reduces welding material consumption by 30%, making long-term operating costs lower than traditional processes.

A 12kW-class laser enables single-sided welding with double-sided forming for 11mm-thick carbon steel at a speed of 1m/min—three times faster than traditional arc welding—significantly enhancing thick-plate processing efficiency.

Real-time monitoring and adaptive adjustment of welding parameters ensure quality stability. Hybrid technologies (e.g., laser-MIG/MAG, laser-TIG) expand applications across diverse scenarios.

Novel optical designs conquer welding challenges for high-reflectivity metals like aluminum and copper, achieving pore-free precision cladding.

| Materials | Shielding Gas | Welding Speed | Penetration Depth | ||

| 6000W | 12000W | 15000W | |||

| Carbon steel or galvanized sheet | Ar+CO₂ Mixed Gas | 1m/ min | 5mm | 11mm | 14mm |

| 2m/ min | 4mm | 9mm | 11mm | ||

| 3m/ min | 3mm | 6mm | 7mm | ||

| 4m/ min | 2mm | 3mm | 4mm | ||

| 5m/ min | 1mm | 2mm | 3mm | ||

| 6m/ min | 0.6mm | 1mm | 2mm | ||

| Stainless steel | Ar | 1m/ min | 5mm | 10mm | 12mm |

| 2m/ min | 3mm | 8mm | 10mm | ||

| 3m/ min | 2mm | 5mm | 6mm | ||

| 4m/ min | 1.5mm | 2mm | 5mm | ||

| 5m/ min | 1mm | 1mm | 2mm | ||

| 6m/ min | 0.5mm | 0.5mm | 1mm | ||

Handheld Water-cooled Fiber Laser Welding Machine

Handheld Water-cooled Fiber Laser Welding Machine

Tube Laser Cutting Machine

Tube Laser Cutting Machine

Exchangeable Table Fiber Laser Cutting Machine

Exchangeable Table Fiber Laser Cutting Machine