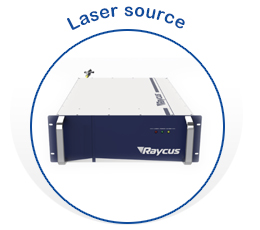

QBH Interface Compatibility : Compatible with leading domestic and international laser brands (TRUMPF, IPG, Raycus, etc.).

Laser power options: 1KW–10KW.

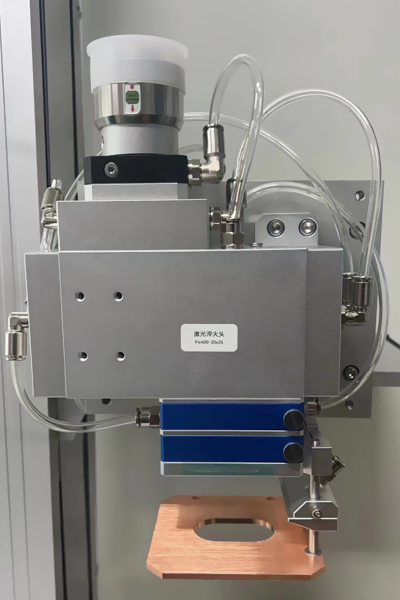

Cladding Head Flexibility: Switch freely between circular spot and square spot laser patterns.

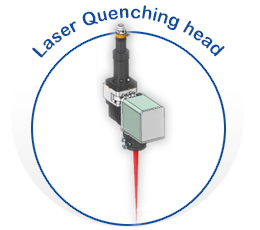

Quenching Head Configurations (Optional):Fixed spot mode;Integral mirror mode;Galvanometer scanning mode.

High-Precision Powder Feeder: Dual-hopper powder feeder with imported servo motor for ultra-stable powder delivery.

Laser Quenching, also known as laser phase transformation hardening, is a technique that uses a focused laser beam to irradiate the surface of a steel material, causing its temperature to rapidly rise above the phase transition point.

When the laser is removed, the inner layer of the material, which is still at a low temperature, quickly conducts heat, allowing the surface layer to quickly cool below the martensitic phase transition point and obtain a hardened layer.

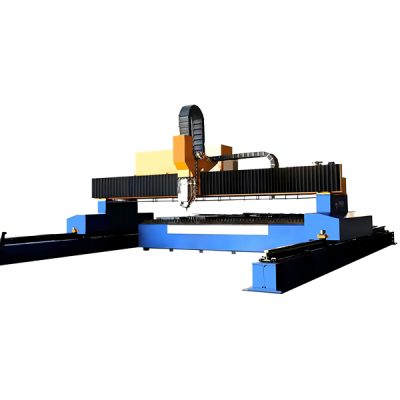

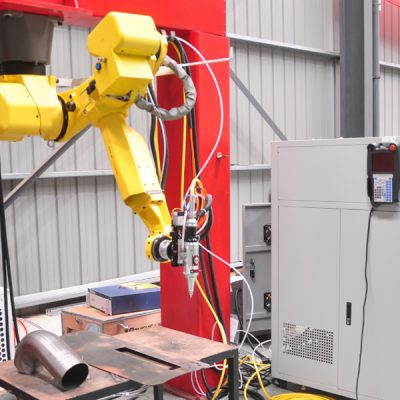

Laser quenching equipment generally consists of several parts, including laser, chiller, beam guiding system (head), machine tool or robot, control system and other components.

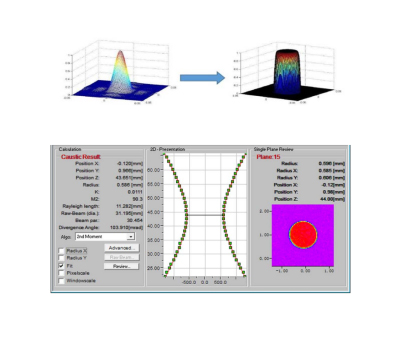

The laser waveform is flat-top light with guided red light after the laser output is homogenized by the homogenizing module.

The laser’s light emitting, light guiding, power output, cooling and software control are designed and manufactured in a fully modularized manner, with each module having a reasonable layout, good heat dissipation, and easy access for maintenance.

The laser itself must have a cooling system to provide cooling for the key components inside the laser.

| Description | Unit | Data |

| Power | W | ≥3000 |

| Mode | Continues | |

| Wavelength | nm | 1080±5 |

| Frequency | HZ | 50-5K |

| Red light power | MW | 0.5-1 |

| Valtage | Three-phase | Four-wire system AC340V-AC420V ~ 50/60hz |

The components of the water cooler system are selected from domestic famous brands to ensure that the equipment has excellent quality and good reliability; high-quality stainless steel chilled water circulating pumps are selected to provide multiple protection functions and passive alarm terminals and remote control terminals, which are easy to realize centralized control and monitoring.

| Description | Unit | Data |

| Compressor power | 7.5 | kW |

| Laser main circuit cooling water flow | 40 | l/min |

| Flow rate of cooling water circuit for external optical path | 2.5 | l/min |

| Voltage | 380 / 50 | V/Hz |

| Rated working current | 19.8 | A |

| Description | Unit | Data |

| standard weight | kg | ≈23 |

| Maximum withstand power | W | 4000 |

| collimated focal length | mm | 150 |

| focal length | mm | 800 |

| wavelength range | nm | 900~1100 |

| 1% full deflection angle step response time | ms | 1.2 |

| 10% full deflection angle step response time | ms | 4.5 |

| marking speed | m/s | 0.7 |

| Positioning speed | m/s | 3 |

| scanning angles (scan head 1, scan head 2) | rad | 0.35 |

| Fiber optic interface type | QBH |

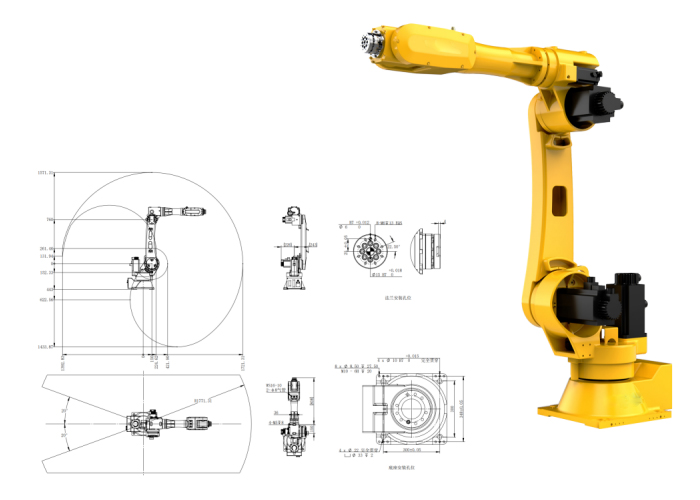

Select domestically produced six axis robotic arms. This robotic arm has high precision, and a special high-precision transmission device can ensure the best process results and extremely high position and path repetition accuracy.

Efficient, with high absolute accuracy and minimal interference profile, it can achieve optimized offline programming.

Optimizing the degree of force, using finite element method (FEM) to optimize the design can achieve high stiffness, thereby balancing the external forces received during the process.

| Description | Parameter |

| Maximum working range | 1721mm |

| Rated load | 35kg |

| Position repetition accuracy | ≤±0.1mm |

| Axial | 6 |

| Protection level | IP54 |

| Rated power | 5kw |

When used in conjunction with a six axis robot, it can compensate for positions that the robot cannot process.

The dual axis displacement machine adopts a high-precision RV reducer, which can accurately achieve repeated positioning accuracy within ± 0.1mm, and the load weight can reach 100kg. The motor adopts an external axis motor of the robot, which can achieve linkage control with the robot. The flipping angle of the positioner is ± 180 °, and the rotation angle is n * 360 °. When cooperating with robots, it can achieve processing requirements at various angles and can process multiple work pieces.

The operation cabinet is equipped with a large screen and high-quality display. Install a Chinese operation interface that can monitor the status of the laser and control the working mode of the laser head. The operation cabinet has high integration and is equipped with an industrial computer, laser, and some electrical equipment.

Laser quenching of harmonic gear

Laser quenching of valve sealing surface

| Name | Technical Parameters |

|---|---|

| Laser Type | Fiber/Semiconductor Laser |

| Output Power | 1 – 10KW (Optional) |

| Laser Wavelength | 1064nm |

| Output Mode | Continuous Wave Output/Pulse |

| Six – Axis Robot | Arm Length 2033mm, Payload 60kg |

| Positioning Accuracy (Six – Axis Robot) | ±0.05mm |

| Maximum Machining Diameter | Ø2000mm |

| Maximum Machining Length | 1300mm |

| Spindle Speed | 0 – 30r/min |

| Maximum Spindle Load – Bearing Capacity | 20000KG |

| Machine Tool Weight | 28000KG |

| Machine Tool Dimensions | 14220x3400x4000mm |

Handheld Water-cooled Fiber Laser Welding Machine

Handheld Water-cooled Fiber Laser Welding Machine

Tube Laser Cutting Machine

Tube Laser Cutting Machine

Exchangeable Table Fiber Laser Cutting Machine

Exchangeable Table Fiber Laser Cutting Machine