Laser cladding is an advanced surface modification technology that uses a high-energy laser beam to fuse premium alloy powders onto metal workpieces, enhancing wear resistance, corrosion protection, and mechanical performance.

Compared to traditional methods, it delivers minimal heat distortion (<5% dilution rate), ultra-dense cladding layers, and pinpoint accuracy for complex geometries like deep holes, grooves, and inner cavities.

| Power consumption | 35kw, 50kw |

|---|---|

| Voltage | AC380V/50Hz |

| Efficiency | 0.3-0.6m/min, 0.7-1.2m/min |

| Powder volume | 20-25g/min, 100-270 mesh |

Ensures the cladding layer retains its original composition and performance, enabling the use of high-performance alloys for tailored surface modifications.

The concentrated laser energy reduces heat-affected zones and substrate deformation, preserving the integrity of the base material.

Dense structure, strong metallurgical bonding, and minimal defects ensure long-lasting durability and superior performance.

Enables accurate strengthening and repair of complex geometries, including deep holes, grooves, and blind holes. A specialized beam guidance system allows for wide cladding layers (20–30mm+ width) with high efficiency.

No pollutants, radiation, or excessive noise, aligning with green manufacturing standards and improving workplace conditions.

The laser waveform is flat-top light with guided red light after the laser output is homogenized by the homogenizing module.

The laser’s light emitting, light guiding, power output, cooling and software control are designed and manufactured in a fully modularized manner, with each module having a reasonable layout, good heat dissipation, and easy access for maintenance.

The laser itself must have a cooling system to provide cooling for the key components inside the laser.

| Description | Unit | Data |

| Power | W | ≥3000 |

| Mode | Continues | |

| Wavelength | nm | 1080±5 |

| Frequency | HZ | 50-5K |

| Red light power | MW | 0.5-1 |

| Valtage | Three-phase | Four-wire system AC340V-AC420V ~ 50/60hz |

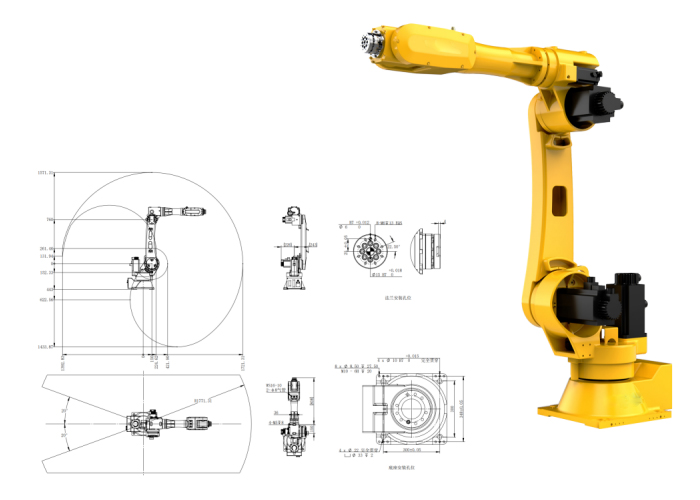

Select domestically produced six axis robotic arms. This robotic arm has high precision, and a special high-precision transmission device can ensure the best process results and extremely high position and path repetition accuracy.

Efficient, with high absolute accuracy and minimal interference profile, it can achieve optimized offline programming.

Optimizing the degree of force, using finite element method (FEM) to optimize the design can achieve high stiffness, thereby balancing the external forces received during the process.

| Description | Parameter |

| Maximum working range | 1721mm |

| Rated load | 35kg |

| Position repetition accuracy | ≤±0.1mm |

| Axial | 6 |

| Protection level | IP54 |

| Rated power | 5kw |

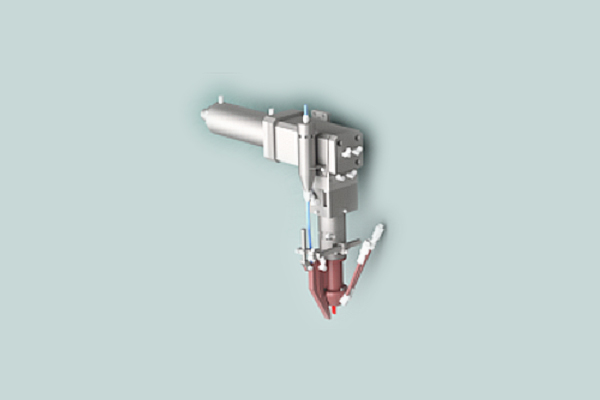

Laser lens three anti-device: anti-reflection, anti-collision, anti-smoke pollution.

High-power laser processing welding head, using the whole internal and external water-cooled design, can meet the 24-hour continuous work, the welding head can be equipped with infrared temperature measurement function, can be online real-time temperature monitoring, with power automatic adjustment function. It adopts drawer type protective mirror holder, which has the advantages of compact structure, fast and simple replacement. Focal length can be customized.

| Description | Data |

| Collimation focal length | 150mm |

| Focusing Focus | 400mm |

| Colling | Integral optical path fully water-cooled |

| Cooling water pressure | Pressurization 8kg |

| Aperture | 40mm |

| Spot Type | Rectangle 2mm×12mm (circular optional, Size optional) |

The FEDSFQ012 is a high-precision volumetric powder feeder designed for single or dual-cylinder operation, utilizing a quantized feeding disk and carrier air to ensure consistent powder conveyance. Ideal for thermal spraying, laser cladding, plasma coating, and 3D printing, it delivers exceptional repeatability of ±1% and handles powders with particle sizes of 20–200 µm.

±1% feeding consistency for reliable process control.

Suitable for diverse powders (metallic, ceramic, composite) used in thermal spray, laser deposition, and additive manufacturing.

Disk rotation speed: 0–6 RPM (custom ranges available). Powder slot dimensions: Standard 20 mm (width) × 1 mm (depth) (customizable). Continuous volume adjustment for flexible feed rates.

Compatible with laser cladding, plasma spray, 3D printing, and other powder-fed systems.

| Description | Data |

| Feeding repetition accuracy | ±1% |

| Conveying granularity | 20~200µm |

| Feeding pan speed | 0~6r/min |

| Maximum powder delivery | 1 – 70 (customizable) g/min |

| Feeding tank size | 20×1 (Width x Depth)(customizable) mm |

| Net weight | ≈60kg |

The components of the water cooler system are selected from domestic famous brands to ensure that the equipment has excellent quality and good reliability; high-quality stainless steel chilled water circulating pumps are selected to provide multiple protection functions and passive alarm terminals and remote control terminals, which are easy to realize centralized control and monitoring.

| Description | Unit | Data |

| Compressor power | 7.5 | kW |

| Laser main circuit cooling water flow | 40 | l/min |

| Flow rate of cooling water circuit for external optical path | 2.5 | l/min |

| Voltage | 380 / 50 | V/Hz |

| Rated working current | 19.8 | A |

The operation cabinet is equipped with a large screen and high-quality display. Install a Chinese operation interface that can monitor the status of the laser and control the working mode of the laser head. The operation cabinet has high integration and is equipped with an industrial computer, laser, and some electrical equipment.

When used in conjunction with a six axis robot, it can compensate for positions that the robot cannot process.

The dual axis displacement machine adopts a high-precision RV reducer, which can accurately achieve repeated positioning accuracy within ± 0.1mm, and the load weight can reach 100kg. The motor adopts an external axis motor of the robot, which can achieve linkage control with the robot. The flipping angle of the positioner is ± 180 °, and the rotation angle is n * 360 °. When cooperating with robots, it can achieve processing requirements at various angles and can process multiple work pieces.

Efficient Water-Cooling.All the water, light, gas and powder circuits are intergrated inside the laser cladding head with the high cooling performance. Multifunctional Design.It can be adapted to a variety of nozzles such as lateral and coaxial powder feeding to meet multiple scenarios. Enclosed Design.With fully enclosed dust-proof design, avoid dust contamination of the optical part. Adjustable Spot Size. Change the spot size at processing position by adjusting the collimation lens.

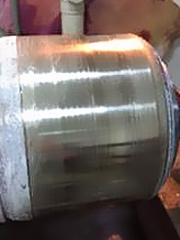

Shaft sleeve laser cladding with copper alloy

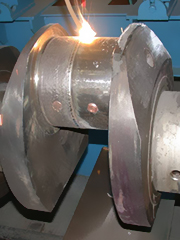

Crankshaft cladding

Cladding sample

| Name | Technical Parameters |

|---|---|

| Laser Type | Fiber/Semiconductor Laser |

| Output Power | 1 – 10KW (Optional) |

| Laser Wavelength | 1064nm |

| Output Mode | Continuous Wave Output/Pulse |

| Six – Axis Robot | Arm Length 2033mm, Payload 60kg |

| Positioning Accuracy (Six – Axis Robot) | ±0.05mm |

| Maximum Machining Diameter | Ø2000mm |

| Maximum Machining Length | 1300mm |

| Spindle Speed | 0 – 30r/min |

| Maximum Spindle Load – Bearing Capacity | 20000KG |

| Machine Tool Weight | 28000KG |

| Machine Tool Dimensions | 14220x3400x4000mm |

Handheld Water-cooled Fiber Laser Welding Machine

Handheld Water-cooled Fiber Laser Welding Machine

Tube Laser Cutting Machine

Tube Laser Cutting Machine

Exchangeable Table Fiber Laser Cutting Machine

Exchangeable Table Fiber Laser Cutting Machine