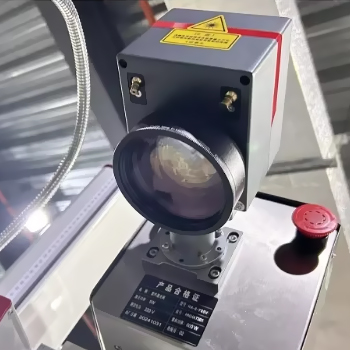

The 5W UV Laser Marking Machine adopts a customized high-speed flying marking control system, offering higher precision and faster speed!

The 5W UV Laser Marking Machine has a wavelength of 355 nm and boasts an extremely high absorption rate. The ultraviolet laser will not damage the materials. Therefore, the ultraviolet laser marking machine is capable of processing materials such as plastics, glass, and ceramics with minimal thermal damage.

| Output Spot Size | TEM00 (M2≤1.2) |

|---|---|

| High-speed Line Speed | High-speed 14000mm/s |

| Marking Character Speed | 300 characters/s (Roman font, character height 1mm) |

| Marking Precision | ≤3 – 5μm |

| Standard Depth | ≤1mm (depending on material) |

| Marking Range | Focus lens F = 160mm, range 100×100mm (standard), optional ranges 0 – 500mm |

| Working Distance | 160mm±2mm (160 focus lens) |

The Buva 5W UV Laser Marking Machine adopts advanced laser technology, enabling it to achieve perfect marking results on certain plastics, glass, ceramics, and a variety of other organic or heat – sensitive materials.

The UV laser marking machine Using high-performance ultraviolet laser (intracavity frequency doubling technology + TEC refrigeration technology), the laser beam quality is superior, bringing users a delicate and beautiful marking effect;

The UV Laser Marking Machine, with a 355nm UV laser wavelength, has an extremely small heat - affected zone, exerting almost no thermal influence on materials, thus preventing material deformation, damage, or scorching.

The marking speed is fast and the efficiency is high; the whole machine has stable performance, small size, low power consumption, and 24-hour continuous and stable operation;

Small size,laser penetration reachesover90%,suitableforharshenvironments and the focused spotis more fine and uniform. High transmitance, strongtransparency,high definition. clearfocus, good marking

Flexible installation ways enable convenient adjustment of the installation position. The flying model is specifically designed for high-speed production lines. It can be flexibly integrated with production lines for installation and operation. The frame can be adjusted by moving it up, down, left, and right. Additionally, the marking head can rotate 360° for marking tasks.

Precise Ruler:A high-precision ruler improves the effectiveness and efficiency of operations, enabling more accurate measurements and markings.

Lift Handle:The hand-crank lift mechanism allows for easy adjustment of the marking position at different heights, providing convenient and flexible operation.

10.2-inch handheld color touchscreen.Automatically generateproduction date, serial number, batchnumber Support pipeline mode,support multiple languages, easy tooperate and learn.

Original:China

Original brand of water coolingsystem,keep the good performanceof cooling and marking

Fill coolant to the marked water level line (avoid overfilling or underfilling); use distilled or deionized water to prevent mineral deposits from clogging the water channels. When ambient temperature falls below 10°C, antifreeze or anhydrous ethanol must be added.

The Hanli water chiller is typically equipped with temperature display - maintain water temperature around 20°C, with 22°C being optimal. Never start the welder without water circulation, as this will burn out the welding torch or damage equipment.

Handheld Water-cooled Fiber Laser Welding Machine

Handheld Water-cooled Fiber Laser Welding Machine

Tube Laser Cutting Machine

Tube Laser Cutting Machine

Exchangeable Table Fiber Laser Cutting Machine

Exchangeable Table Fiber Laser Cutting Machine