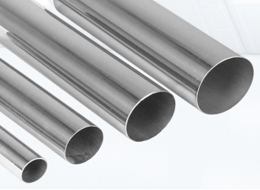

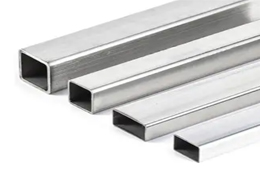

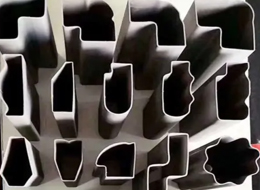

The 5-axis manual-loading laser tube cutting machine offers comprehensive tube cutting functions, capable of processing square tubes, round tubes, triangular tubes, elliptical tubes, and various other special-shaped tubes with high precision and efficiency. Featuring an industrial-styled overall design, the equipment has been widely adopted in domestic industries such as fitness equipment, school furniture and teaching tools, and display shelving.

| Processing Pipe Length | 6m, 9m, 12m |

|---|---|

| Laser Power | 1500W-12000W |

| X/Y Axis Positioning Accuracy | ±0.03mm/m |

| X/Y Axis Repeat Positioning Accuracy | ±0.03mm/m |

| Maximum Acceleration | 1.2G |

| Rapid Traverse Maximum Speed | 100m/min |

| Tail Scrap Remainder | 110-240mm |

| Electricity demand | 380V/50Hz |

The machine tool structure features an integrated ramp design, making loading and unloading more convenient and enhancing human-machine interaction efficiency.

Import drawings, utilize software for intelligent nesting to optimize material usage, then export and load the machining program to the machine.

Move metal tubes to the equipment area per production needs, and place them on the loader or rack for standby.

Clamp the tube, set matching process parameters, check air assist, laser, and motion functions, then initiate cutting.

The machine completes cutting automatically per the program, with finished parts automatically unloaded, inspected, and transferred to the next process.

| Item | Specification |

| Name | 5-Axis Fiber Laser Tube Cutting Machine |

| Processing Tube Length | 6000mm | 9000mm | 12000mm |

| Processing Round Tube Range | 10-120mm | 10-165mm | 10-220mm | 20-350mm |

| Processing Square Tube Range | 10-84mm | 10-115mm | 10-155mm | 20-245mm |

| X/Y Axis Positioning Accuracy | ±0.03mm/m |

| X/Y Axis Repeat Positioning Accuracy | ±0.03mm/m |

| Maximum Acceleration | 1.2G |

| Maximum Empty Travel Speed | 100m/min |

| Laser Power | 1500W-12000W |

| Maximum Chuck Rotation Speed | 200/130/120/80 r/min |

| Tail Material Remainder | 110-240mm |