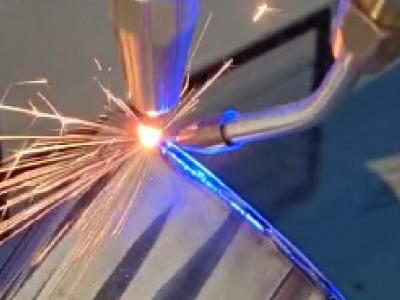

The machine adopts high-performance fiber laser, high-precision servo motor and multi-axis linkage control system to realize the automatic welding of high-precision metal workpiece with complex trajectory

| Laser power | 1500W, 2000W, 3000W, 6000W |

|---|---|

| Working voltage | AC220V 50Hz/60Hz |

For aerospace and automotive manufacturing's critical welds.

Applied in home appliances, electronics, and hardware.

Ideal for medical equipment, watches, jewelry, and new energy batteries.

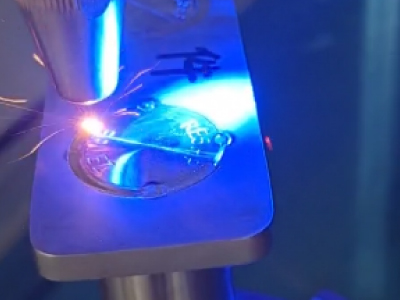

Equipped with a CCD monitoring system and advanced control software, the fiber laser welding machine can precisely position and automatically focus on welding parts, creating high-tensile and tight seams with the highest visual quality. With the help of fixtures and rotating devices, you can enhance welding efficiency by rapidly welding a large number of similar products with a high degree of consistency.

Fill coolant to the marked water level line (avoid overfilling or underfilling); use distilled or deionized water to prevent mineral deposits from clogging the water channels. When ambient temperature falls below 10°C, antifreeze or anhydrous ethanol must be added.

The Hanli water chiller is typically equipped with temperature display - maintain water temperature around 20°C, with 22°C being optimal. Never start the welder without water circulation, as this will burn out the welding torch or damage equipment.

First turn off the welding machine, then allow the water chiller to continue operating for 1-2 minutes before powering down to ensure proper cooling of the welding torch.

Fast welding, high precision, equipped with high-definition CCD monitor, welding seams can be clearly seen welding lines. This welding head has a strong advantage in automatic welding applications and is a cost-effective welding head

Lightweight, compact design structure, reduce the mechanical load of the machine tool

The welding head uses a galvanometer motor to drive the X and Y axis lens to swing, with a variety of swing modes, and the swing welding allows the workpiece to have irregular splicing, larger gap and other processing parameters, which can significantly improve the welding quality; The welding head has excellent performance and supports the function of broken wire detection and continuous light dynamic parameter adjustment

| Brand:BUVAuncom | Model:BV-PAW1500/2000/3000/6000 |

| Laser Power(W) | 1500/2000/3000/6000 |

| Laser Wavelength | 1080nm±10 |

| Laser Lifespan | ≤100000 hour |

| Optic Fiber Length | 10m |

| Orientation Method | Red Light Indication、CCD Inspection |

| Welding Depth(mm) | 0.3-4/6/8/9.5/10 |

| Platform Size(mm) | 1000*1000/1300*970/1600*1000 |

| Module Stroke X/Y/Z Axis(C/A Axis Optional)(mm) | 400*300*400/600*300*400/800*400*400 Optional |

| Supported Vector File Format | DWG、DFX、BMP、JPG、PNG、TIF、PCX、TAG、GIF、PLT |

| Power supply | AC220V/380V 50/60Hz |

| Gross Power | 11kw/13kw/16kw/19kw/23kw |

| machine Dimension | 900*1000*1900mm |

| Warranty | The machine 1 year, the laser 2 years |

Handheld Water-cooled Fiber Laser Welding Machine

Handheld Water-cooled Fiber Laser Welding Machine

Tube Laser Cutting Machine

Tube Laser Cutting Machine

Exchangeable Table Fiber Laser Cutting Machine

Exchangeable Table Fiber Laser Cutting Machine