This month, the production line at BUVAuncom has been operating at full capacity once again, successfully assembling and calibrating a customized laser marking machine for our second client this month. Upholding our consistent principle of “Quality First, Customer Foremost,” every unit must pass our rigorous performance verification process before shipment.

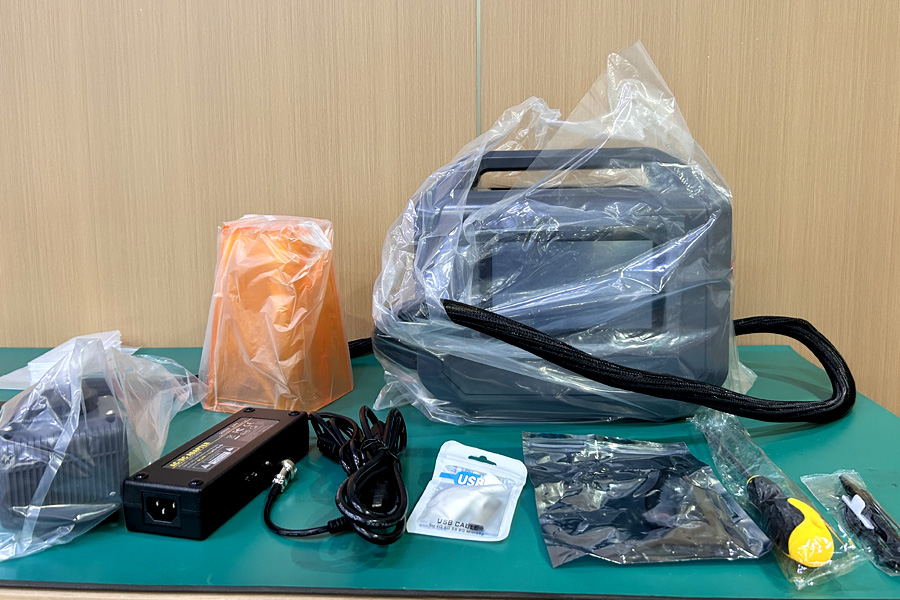

Prior to delivery, our professional technical team conducted comprehensive performance tests on the entire machine to ensure its marking precision, speed, and stability all meet the highest standards. Simultaneously, we meticulously inspected all accessories to guarantee nothing is overlooked. After confirming everything is flawless, the machine was carefully packed and is now ready for shipment. It awaits dispatch to the client’s site, where it will soon provide a boost to their production operations.

The successful completion and quality inspection of this laser marking machine not only demonstrates our stable production capacity but also highlights our firm commitment to delivering perfect products. We firmly believe that reliable equipment is the cornerstone of our clients’ success. BUVAuncom will continue to dedicate itself to providing clients with high-quality laser equipment and a worry-free service experience.

BUVA Technology Co., Ltd is a laser company that mainly solves problems in laser industrial manufacturing, such as laser cutting of metal sheets, precision welding of electronic components, laser marking on metals, ceramics, glass, etc., as well as laser quenching and cladding technologies focusing on surface treatment.