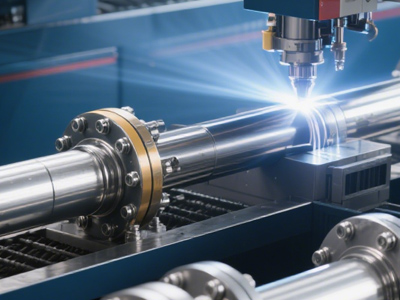

Our professional tube-sheet dual-purpose laser cutting machine seamlessly combines the strengths of traditional flatbed laser cutters and specialized tube laser cutting systems. Engineered for industrial-grade performance, it delivers.

| Laser Power | 1000W-15000W |

|---|---|

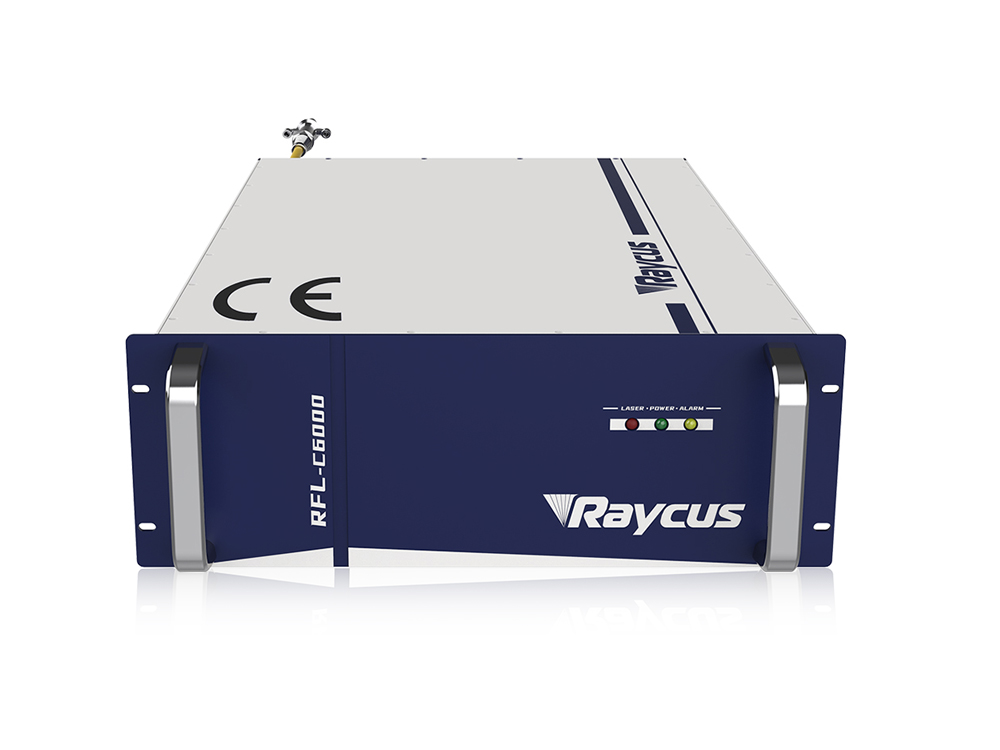

| Laser Brand | Raycus |

| Laser Wavelength | 1070nm |

| Z Axis Move Distance | 280mm |

| Pipe Cutting Length | 6000mm |

| Pipe Cutting Thickness | 6-12mm |

| Pipe Cutting Diameter | 20-220mm |

| Positioning accuracy | ±0.03mm/m |

| Repeat positioning accuracy | ±0.02mm |

| Power Supply | 380V/50HZ |

| Cooling Mode | Water Cooling |

| Operating temperature of machine | 0℃-40℃ |

| Operating humidity of machine | 5%-90% |

| Machine Weight | 60000-13000KG(according to different machine size) |

| Machine Size | 15000*4600*2600mm |

| Other machine size options | 3000x1500mm, 4000x1500mm, 6000x1500mm, 8000x1500mm, 3000x2000mm, 4000x2000mm, 6000x2000mm, 8000x2000mm |

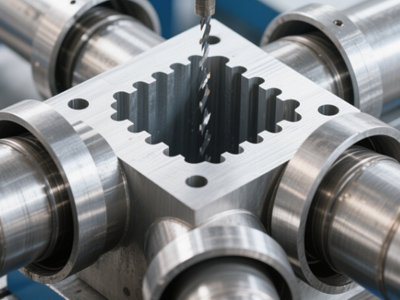

Cut multi-directional cylindrical intersecting holes on main pipes (varying diameters), Process both eccentric & concentric perpendicular intersections between branch/main pipes

Precision-cut cylindrical intersecting ends on branch pipes Handle perpendicular & angled intersections (0-90°) Create perfect beveled ends on round tubes

Cut square holes & oval slots in round tubes Process ring main pipe intersections with branch pipes Full 360° cutting on square/rectangular tubes

Steel pipes: seamless cutting & truncation, Specialty profiles: square/oval/U-shaped/rectangular tubes

Precision Temperature-Control Display Water Chiller ,our chiller’s compressor (imported famous brand), evaporator with high-quality titanium tubes (Stainless Steel Plate evaporator for non-standard products), circulating multi-stage pumps with stainless steel materials, refrigerant drying systems use filters, thermal expansion valve to get high-quality, high efficiency and low noise’s performance.

And turbo flow intellectual switch is for controlling the temperature of cooling water in laser lamp;the flow control is for ensuring long-term continuously operation of the laser generator.

famous brand auto focus laser cutting head+follower system with condenser sensor, water cooling and anti-collision device function.

Can make much more faster penetrate than normal manual focus cutting head.

| Laser Power | 1000W-15000W |

| Laser Brand | Raycus |

| Laser Wavelength | 1070nm |

| Z Axis Move Distance | 280mm |

| Pipe Cutting Length | 6000mm |

| Pipe Cutting Thickness | 6-12mm |

| Pipe Cutting Diameter | 20-220mm |

| Positioning accuracy | ±0.03mm/m |

| Repeat positioning accuracy | ±0.02mm |

| Power Supply | 380V/50HZ |

| Cooling Mode | Water Cooling |

| Operating temperature of machine | 0℃-40℃ |

| Operating humidity of machine | 5%-90% |

| Machine Weight | 60000-13000KG(according to different machine size) |

| Machine Size | 15000*4600*2600mm |

| Other machine size options | 3000x1500mm, 4000x1500mm, 6000x1500mm, 8000x1500mm, 3000x2000mm, 4000x2000mm, 6000x2000mm, 8000x2000mm |

| Cutting parameters | 6kw | 12kw | 20kw | ||||||

| Material | Thickness(mm) | Speed(m/min) | Pressure(bar) | Thickness(mm) | Speed(m/min) | Pressure(bar) | Thickness(mm) | Speed(m/min) | Pressure(bar) |

| Mild steel (O2) | 1 | 8.0-10.0 | 0.7 | 1 | 8.0-10.0 | 0.7 | 1 | 8.0-10.0 | 2.5 |

| 5 | 2.5-2.8 | 1 | 5 | 2.5-2.8 | 1 | 5 | 2.5-2.8 | 0.7 | |

| 10 | 1.1-1.2 | 1 | 10 | 1.2-1.3 | 1 | 10 | 1.2-1.3 | 0.65 | |

| 16 | 0.75-0.85 | 1 | 16 | 0.9-1.0 | 1 | 16 | 0.9-1.0 | 0.65 | |

| 25 | 0.40-0.60 | 1.1 | 25 | 0.5-0.6 | 1.1 | 25 | 0.5-0.6 | 1 | |

| 30 | 0.4-0.5 | 1.2 | 30 | 0.3-0.55 | 1.1 | ||||

| 40 | 0.2-0.3 | 1.2 | 40 | 0.25-0.35 | 1.4 | ||||

| 50 | 0.20-0.28 | 2 | |||||||

| 60 | 0.15-0.21 | 2 | |||||||

| Stainless steel (N2) | 1 | 50-60 | 10 | 1 | 50-60 | 10 | 1 | 50-60 | 9 |

| 8 | 3.5-4.0 | 10 | 8 | 10-14 | 10 | 8 | 14-17 | 7-12 | |

| 10 | 2.5-3 | 8 | 10 | 6-10 | 8 | 10 | 10-13 | 7-12 | |

| 25 | 0.2-0.27 | 8 | 25 | 0.6-1.0 | 8 | 25 | 1.4-1.8 | 7-12 | |

| 30 | 0.3-0.7 | 15 | 30 | 0.9-1.2 | 7-12 | ||||

| 40 | 0.15-0.3 | 15 | 40 | 0.2-0.5 | 18 | ||||

| 50 | 0.15-0.2 | 18 | |||||||

| 60 | 0.1-0.13 | 18 | |||||||

| Aluminium (AIR) | 1 | 40.0-50.0 | 12 | 1 | 50-60 | 12 | 1 | 50-60 | 10 |

| 5 | 10.0-12.0 | 12 | 5 | 28-38 | 12 | 5 | 33-35 | 10 | |

| 10 | 1.2-1.8 | 12 | 10 | 4.0-6.0 | 10 | 10 | 8.5-11 | 10 | |

| 16 | 0.3-0.6 | 10 | 16 | 1.0-1.5 | 10 | 16 | 2.8-3.4 | 10 | |

| 25 | 0.4-0.6 | 10 | 25 | 0.8-1 | 10 | ||||

| 30 | 0.2-0.4 | 10 | 30 | 0.5-0.7 | 12 | ||||

| 40 | 0.3-0.4 | 12 | |||||||

| 50 | 0.1-0.15 | 12 | |||||||

Handheld Water-cooled Fiber Laser Welding Machine

Handheld Water-cooled Fiber Laser Welding Machine

Tube Laser Cutting Machine

Tube Laser Cutting Machine

Exchangeable Table Fiber Laser Cutting Machine

Exchangeable Table Fiber Laser Cutting Machine