To better meet the growing market demand for customized, high-precision metal processing, BUVA’s new Process Room is now officially operational. Built to industrial standards as a “Process Validation Center,” it is designed to provide new and existing clients with solid R&D support and rapid prototyping services, guiding products from concept to mass production.

Professional Environment: The Starting Point of Precision Validation

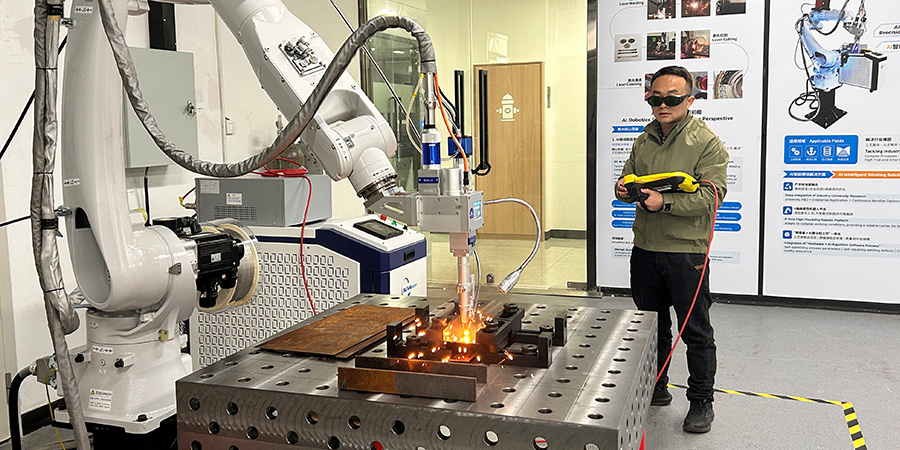

Powerful Equipment: 3kW Robotic Laser Welding System

The star of the Process Room—the 3kW Robotic Laser Welding System—is ready for action. Integrating a six-axis robotic arm, Raycus laser, Wanshunxing welding head, Hanli water chiller, and an intelligent control system, it combines strength with precision. Capable of handling complex 3D trajectory welding and deep penetration welding for thick plates, it maintains extremely high stability over long operating periods, ensuring that process parameters tested on samples can be fully replicated in mass production. Simply provide your requirements or samples, and we will review and develop a feasible solution, using professional equipment to validate the process.

Professional Environment: The Starting Point of Precision Validation

We offer not only laser welding solutions but also comprehensive precision laser cutting capabilities. Whether for materials such as stainless steel, carbon steel, and aluminum alloy, or plates of varying thicknesses and profiles of different shapes, we can customize exclusive cutting solutions and deliver high-quality test samples based on your needs.

Act Now, Validate Your Ideas

BUVA’s new Process Room aims to become your trusted R&D partner. We warmly invite partners and clients to visit us or submit your requirements to experience our professional complimentary laser sampling and welding process evaluation services. Let’s work together with precision craftsmanship to achieve excellence in your products.

Contact us to begin your sample validation journey.