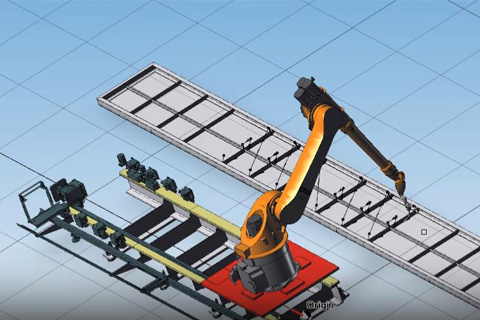

Robotic laser welding: It has a high degree of automation, a fast welding speed, and stable welding quality, making it suitable for automated welding in mass production.

| Controlled Axes | 6 Axes |

|---|---|

| Repeatability | ±0.03 mm |

| Drive Method | Electric servo drive by AC servo motor |

| Installation methods of robotic arms | Floor, Upside-down, Wall mount |

| Laser power | 1500W, 2000W, 3000W, 6000W |

Laser welding is a precision joining process that utilizes a high-energy-density laser beam as a heat source to melt and fuse two or more metal surfaces together.

Laser welding operates by concentrating a high-power laser beam through a focusing lens, creating an intense heat spot that instantly melts the metal surfaces. The molten material then solidifies upon cooling, forming a precise and high-strength weld seam.

6-axis joints, with a payload of 15 kg and arm lengths of 1400 mm / 2000 mm.

An open-type controller is adopted, which can communicate with various laser welding equipment.

±0.03 mm, meeting the requirements of precision laser welding.

IP67, suitable for harsh industrial environments.

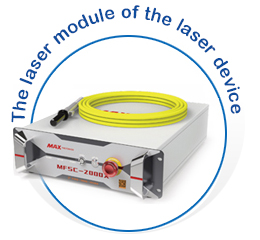

This high-power laser integrates exceptional power output, compact design, user-friendly operation, superior beam quality, and high photoelectric conversion efficiency into a single system. It meets the demands of precision machining while significantly enhancing welding performance and highly reflective material cutting capabilities. Ideal for remote processing applications, the module can be quickly and seamlessly integrated into machine tools, robotic systems, and automated production lines for large-scale manufacturers.

The robotic welding process is stable, with high-quality weld seams and reduced welding defects.

| Model | Arm Span (mm) | Laser Power | Applicable Materials | Plate Thickness |

| BUVA1214 – 1500 | 1400 | 1500W | Carbon steel, stainless steel, aluminum alloy, titanium alloy, etc. | 0.5 – 3mm |

| BUVA1214 – 2000 | 1400 | 2000W | Carbon steel, stainless steel, aluminum alloy, titanium alloy, etc. | 0.5 – 4mm |

| BUVA1214 – 3000 | 1400 | 3000W | Carbon steel, stainless steel, aluminum alloy, titanium alloy, etc. | 0.5 – 5mm |

| BUVA1220 – 1500 | 2000 | 1500W | Carbon steel, stainless steel, aluminum alloy, titanium alloy, etc. | 0.5 – 3mm |

| BUVA1220 – 2000 | 2000 | 2000W | Carbon steel, stainless steel, aluminum alloy, titanium alloy, etc. | 0.5 – 4mm |

| BUVA1220 – 3000 | 2000 | 3000W | Carbon steel, stainless steel, aluminum alloy, titanium alloy, etc. | 0.5 – 5mm |

| BUVA2518 – 6000 | 2000 | 6000W | Carbon steel, stainless steel, aluminum alloy, titanium alloy, etc. | 0.5 – 10mm |

Handheld Water-cooled Fiber Laser Welding Machine

Handheld Water-cooled Fiber Laser Welding Machine

Tube Laser Cutting Machine

Tube Laser Cutting Machine

Exchangeable Table Fiber Laser Cutting Machine

Exchangeable Table Fiber Laser Cutting Machine